Achieve Smart Manufacturing Efficiency

Data can be collected, analyzed, managed, and integrated at scale with Alleantia to reach manufacturing efficiency.

OVERALL EQUIPMENT EFFECTIVENESS

PRODUCTION OPERATING COSTS

Due to the wide range of machinery and apps in manufacturing plants, communication is hard.

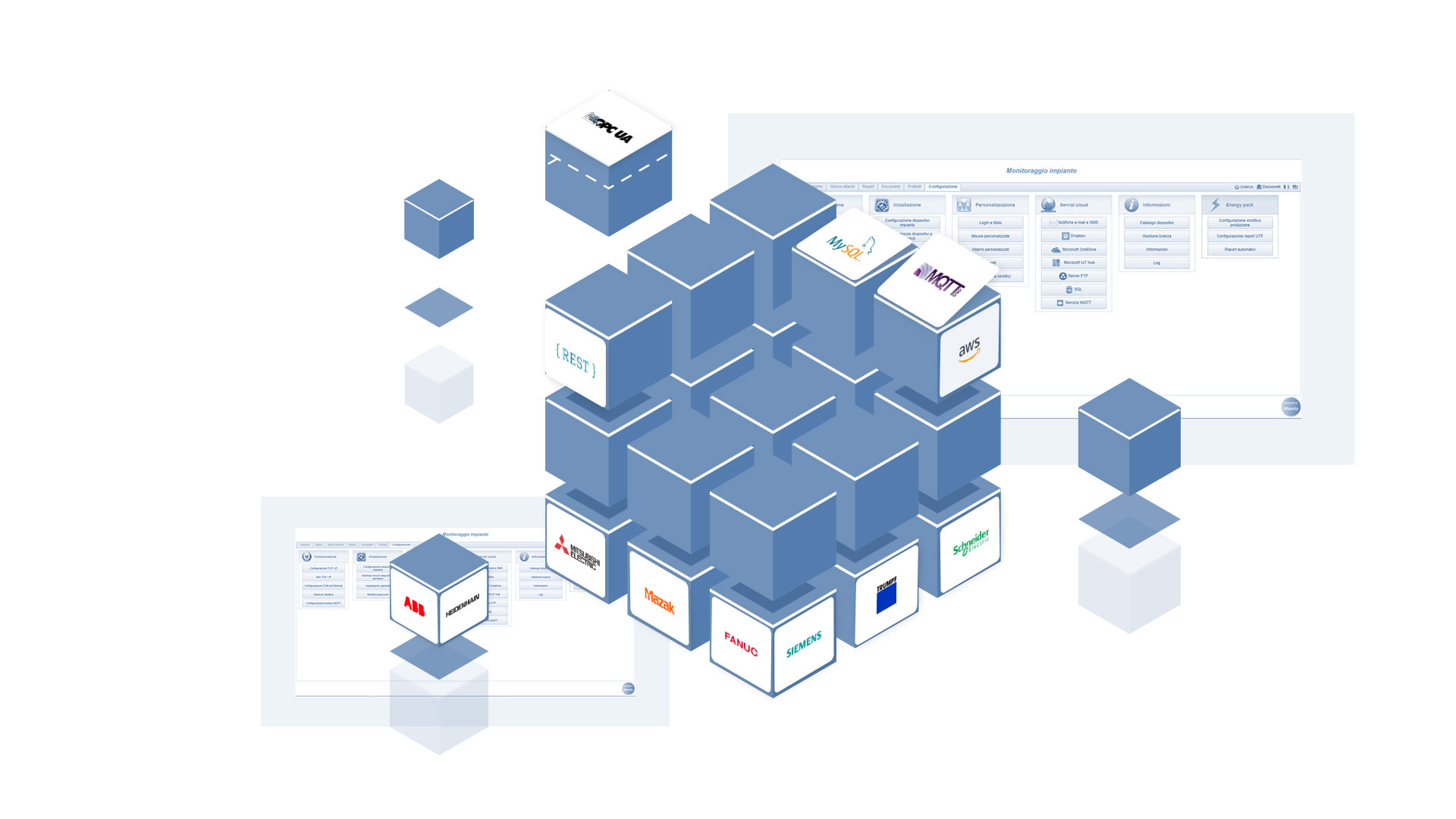

Through a standardized communication layer, Alleantia platforms solves the challenge of connecting to any factory data source, gathering data in real time, and integrating with IT systems.

With Alleantia, you can manage and orchestrate all devices, data, and apps across all factories.

Using one platform for collecting, analyzing, managing and integrating factory data, you can meet all business needs.

With 5.000+ preloaded drivers, you can connect to any PLC, CNC, sensor, robotic system, SCADA/MES/Historian, then collect, process, and normalize data on your own.

After the collection phase, data can be sent to the cloud, data lakes, or an enterprise application, at a predetermined pace that is independent of the actual device reading rate.

To manage different frequencies, a series of parallel streams at different frequencies carrying separate sets of measurements can be triggered concurrently to one or more destinations.

By a quick and cost-effective setup, any new or legacy assets can feed data into many third-party cloud, big data, or business applications for further processing.

With Alleantia, it is easy to establish a connection to and from any asset, collect and process data to integrate it into enterprise and cloud applications to perform advanced analytics.

Alleantia for predictive maintenance provides the asset data collection and alerts needed to reduce unscheduled downtime and increase the efficiency of maintenance activities.

Reduce the number of on-site interventions and simplify with Alleantia, which facilitates remote access to industrial machinery in a completely secure way.

Alleantia facilitates manufacturers’ shift from supplying a product to providing customer-focused services and gains a competitive advantage through outsourcing.

To optimize energy use, save money, and boost efficiency consumption start gathering valuable data on field equipment with Alleantia.