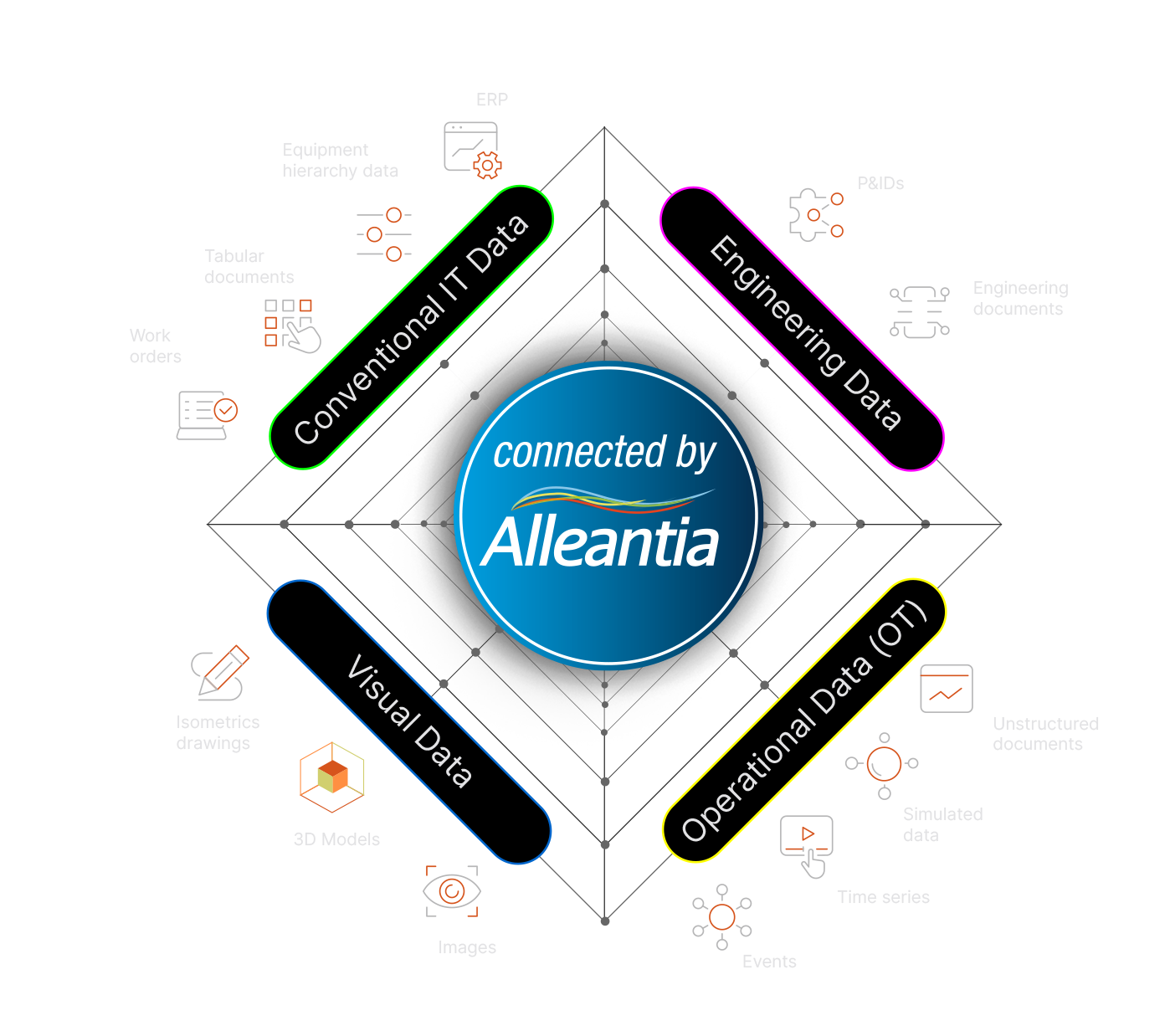

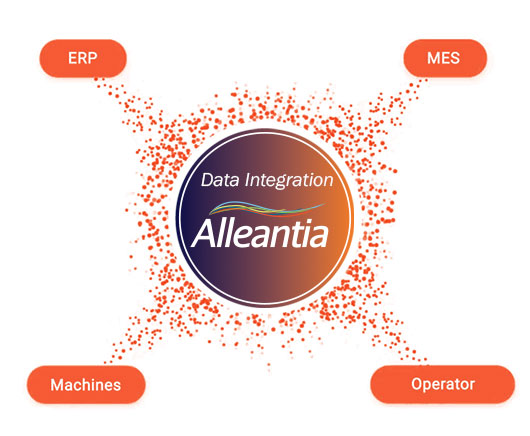

ENHANCES MACHINE DATA WITH CONTEXT DATA

Facilitates process and operation analysis by correlating ‘zero coding’ machine data with application and operator data.

DATA INTEGRATION

ENHANCES MACHINE DATA WITH CONTEXT DATA

Facilitates process and operation analysis by correlating ‘zero coding’ machine data with application and operator data.

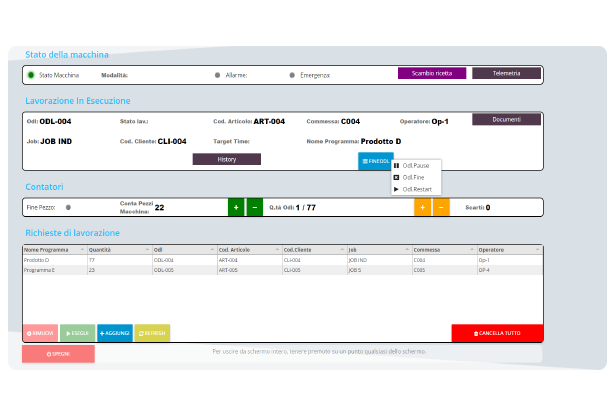

READY-TO-USE OPERATOR INTERFACE

More accurate, timely, and punctual production data management

To make it easier for machine operators to handle manual data, an operator interface is available for displaying production data, and for manual data entry combined with machine data.

The operator interface can be used to enter any type of contextual data to the machine data not provided by applications (e.g., selection of the recipe to be run, stop causalities, etc.).