Discover our in-depth Industiral IoT case studies showcasing the transformative impact of IoT technology in industrial settings. Explore real world applications, innovative solutions, and measurable outcomes that enhance operational effciency, productivity, and safety.

Browse through some real case reports

SECTOR: DESIGN/FURNITURE

END USER

Superevo is a manufacturer of revolutionary upholstery and furniture accessories. The company offers a complete processing approach based on customer requirements. The solution created by Alleantia for Superevo is an advanced interconnection system for data transmission that reduces waiting time from 3D to sample/prototype production.

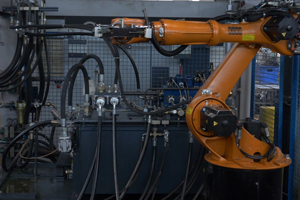

SECTOR: MANUFACTURING

SYSTEM INTEGRATOR

The solution created for Alumotion is a cybersecure interconnection system for the telematic transmission of performance, production, control and monitoring of a robot installed hundreds of kilometres away. Thanks to the data coming from the robot, it is possible to extrapolate diagrams of its operation. This information will be used to identify when to carry out maintenance, to avoid breakdowns and unplanned downtime.

SECTOR: FOOD

END USER

Latteria Soresina, was founded in 1900 as a processing cooperative for the milk produced by its members. Today the company is the first producer in the world of the famous Grana Padano PDO, and occupies leading positions in other Italian excellences. A continuous search for new technologies to digitize its industrial processes has led Alleantia to become an important player for Latteria Soresina to consolidate its leadership in the sector.

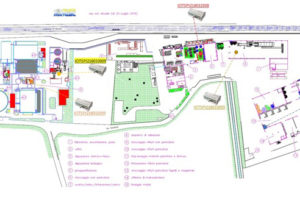

SECTOR: ENERGY

END USER

Ansaldo Energia, leader in the energy sector with an innovative cutting-edge project called Lighthouse Plant of which Alleantia was a key partner, digitizes the entire manufacturing process of the two production sites in Genoa, optimizing predictive production and maintenance processes.

SECTOR: AUTOMOTIVE

END USER

SECTOR: MANIFACTURING

END USER

SECTOR: MANIFACTURING

INDIPENDENT SOFTWARE VENDOR

The Alleantia – Antos Industrial IoT project is the perfect demonstration of how Alleantia’s Plug & Play technology can be integrated in every ISV platform and be used to interconnect different machines to facilitate the work of entire production chains. Read more to find out how Alleantia and Antos BRAVO Mes management software have been able to digitalise and solve production problems of more.

SECTOR: MANIFACTURING

END USER

The Paglieri successful story is the perfect example of what it means to use the IoT power to rethink in a modern key the creation of an historical product. Discover how Alleantia, thanks to the collaboration with leading companies in the IT market such as Cisco and Italtel, has given rise to the digitization of Paglieri, enabling it to reach the highest levels of quality and predictive maintenance.

SECTOR: WASTE DISPOSAL

END USER

Alleantia collects and process information to monitor industrial processing of waste treatment.

Alleantia‘s plug & play technology has played a fundamental role in the iWASTE project and in the development of a unified management platform able to collect and process information to monitor industrial processing of waste treatment. Discover the complete use case to learn how Alleantia is able to transform data from each type of device into essential information for monitoring and enhancing production.