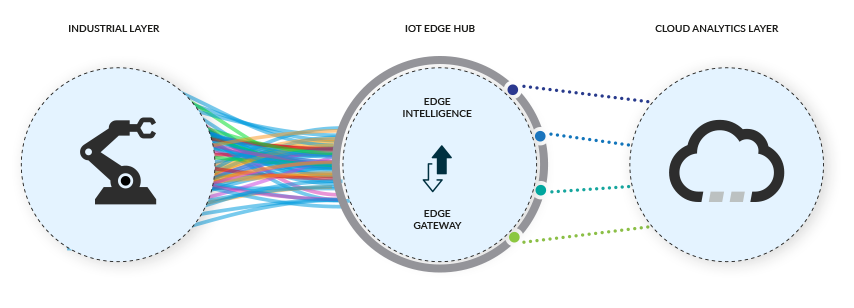

TURNS “PLUG-AND-PLAY” DATA FROM YOUR MACHINES INTO INFORMATION FOR IMMEDIATE USE

ON-EDGE micro applications

for machinery and industrial plants

- Efficiency and quality indicators

- Operating conditions and trends

- Real-time and time-based analysis

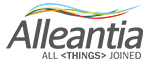

EDGE INTELLIGENCE

TURNS “PLUG-AND-PLAY” DATA FROM YOUR MACHINES INTO INFORMATION FOR IMMEDIATE USE

ON-EDGE micro applications

for machinery and industrial plants

- Efficiency and quality indicators

- Operating conditions and trends

- Real-time and time-based analysis